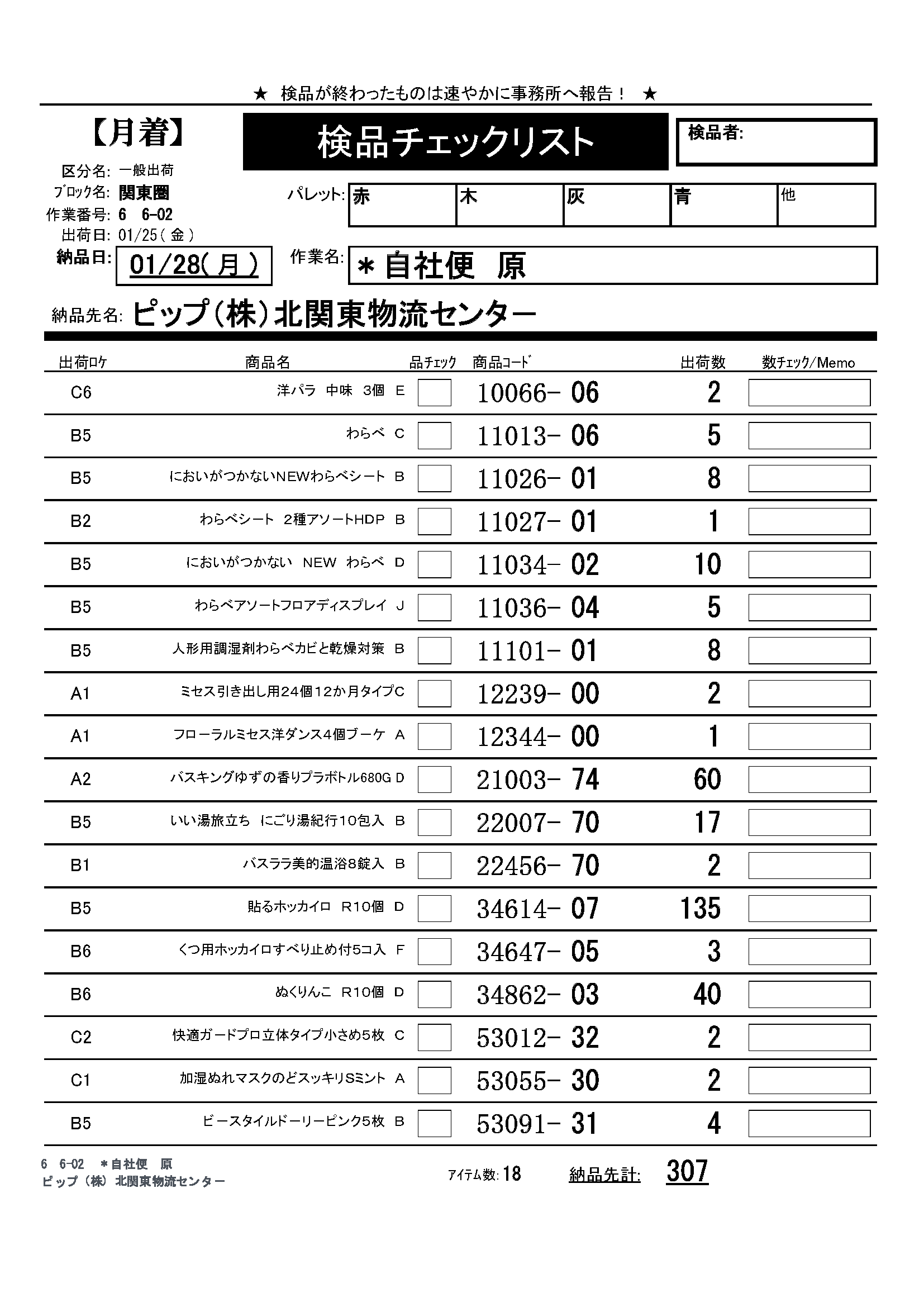

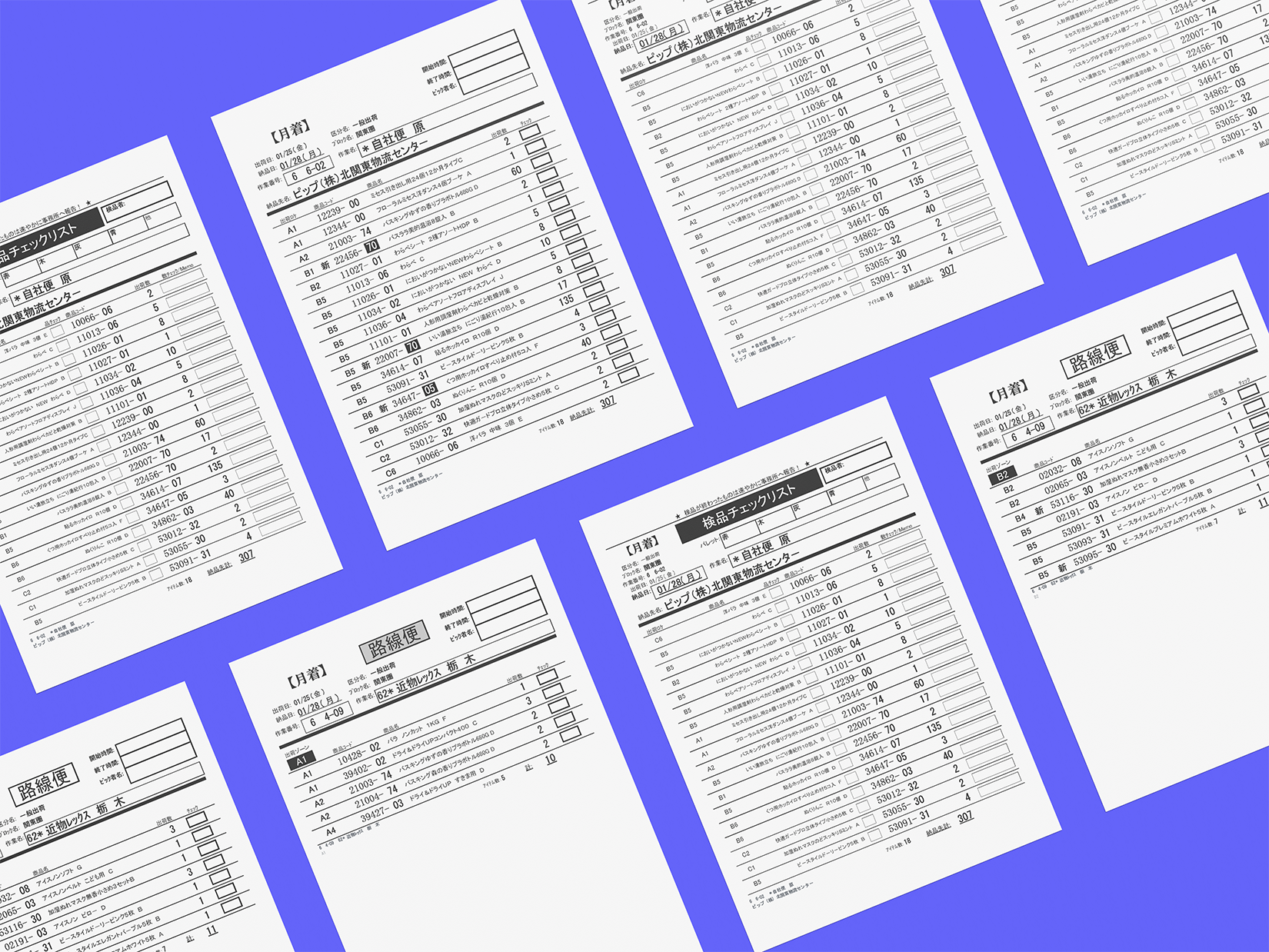

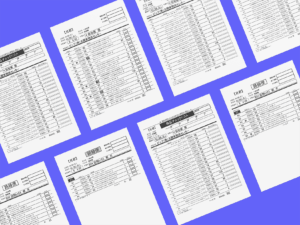

Improved the usability of a poorly sized and unintuitive picking list by leveraging firsthand knowledge of logistics operations.

Problem

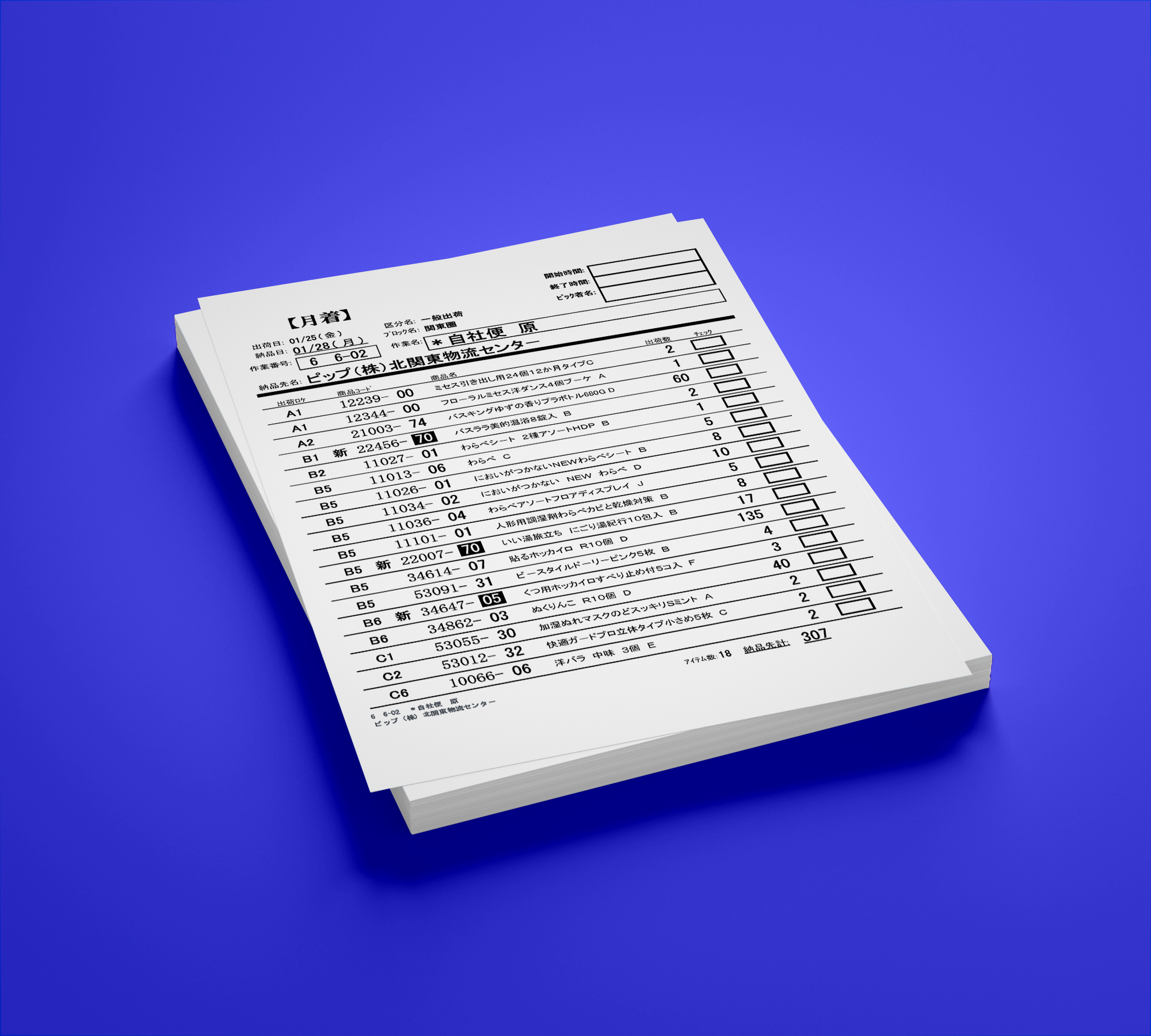

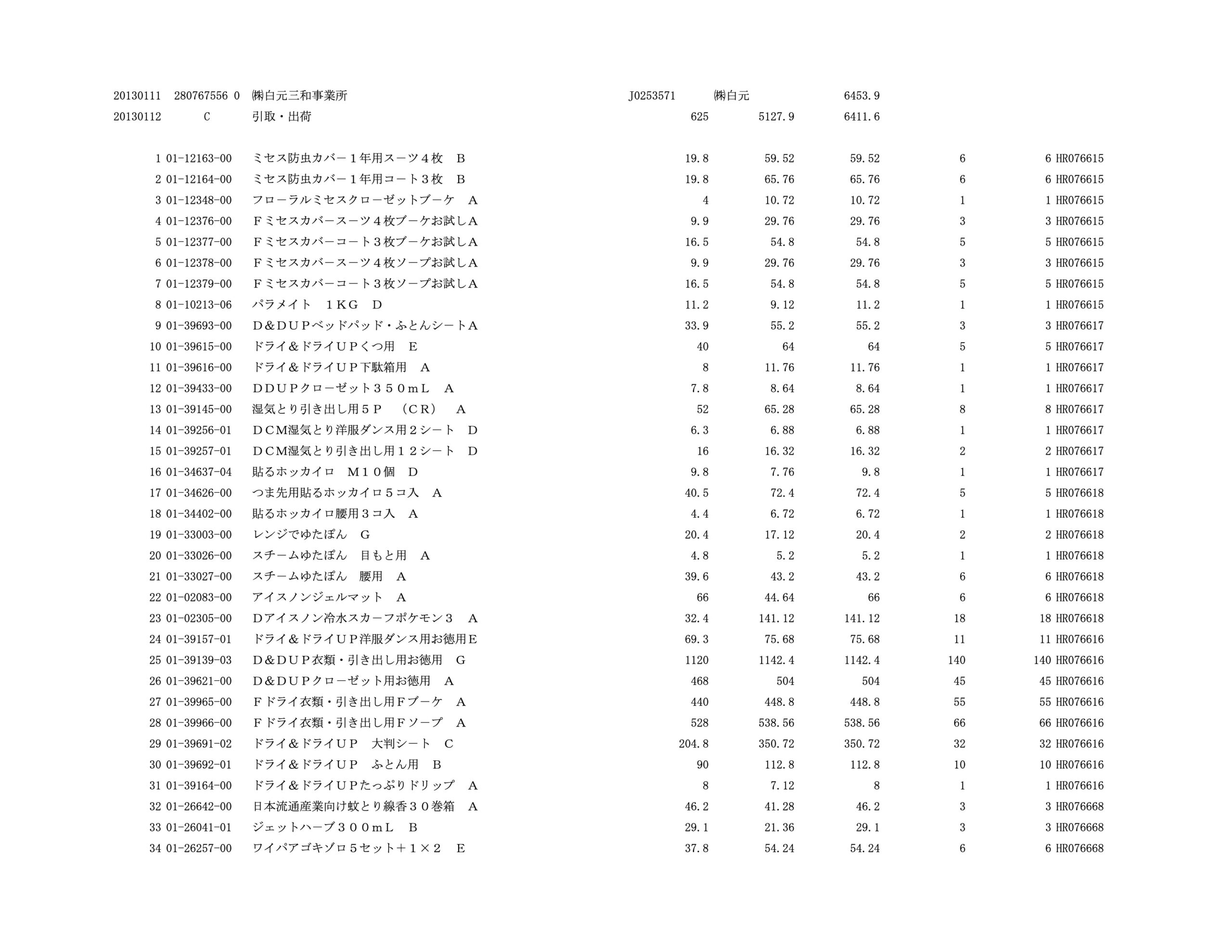

Workers were forced to perform picking tasks using A3-sized picking lists printed on a dot-impact printer. The warehouse was dimly lit, and when the printer ribbon became faint, the text was hard to read. Moreover, the printed item order didn’t correspond to the actual storage layout—only seasoned workers relying on years of intuition could navigate it. Even then, frequent picking errors occurred. Inspection lists were produced under the same low-quality conditions, making error detection difficult.

Challenge

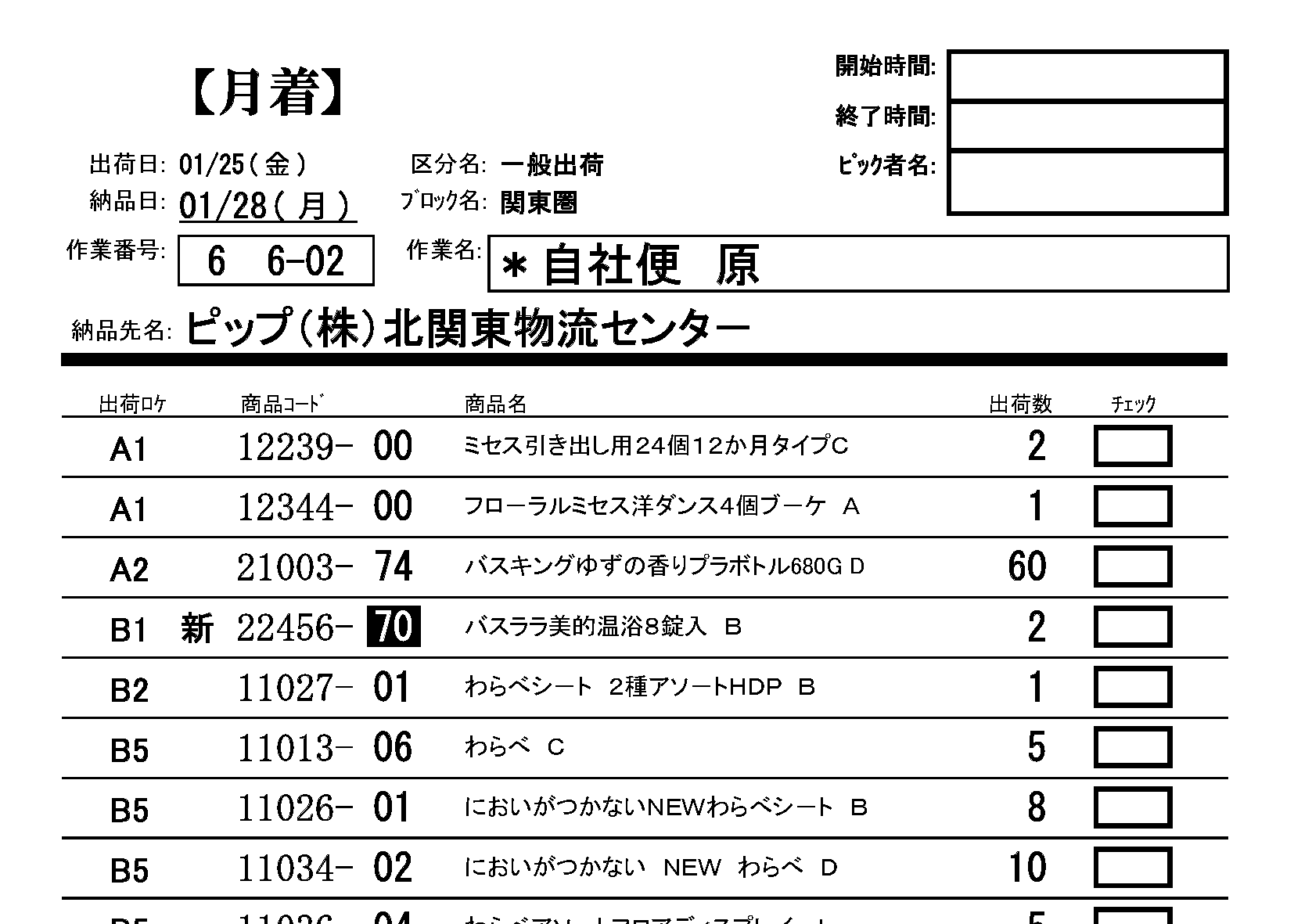

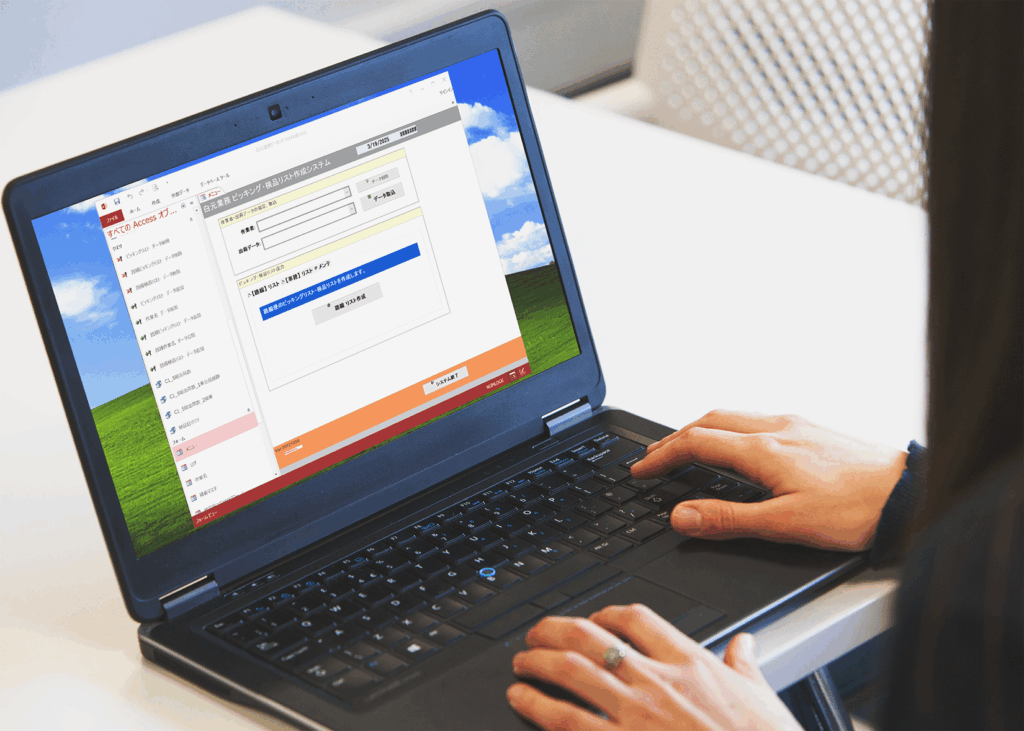

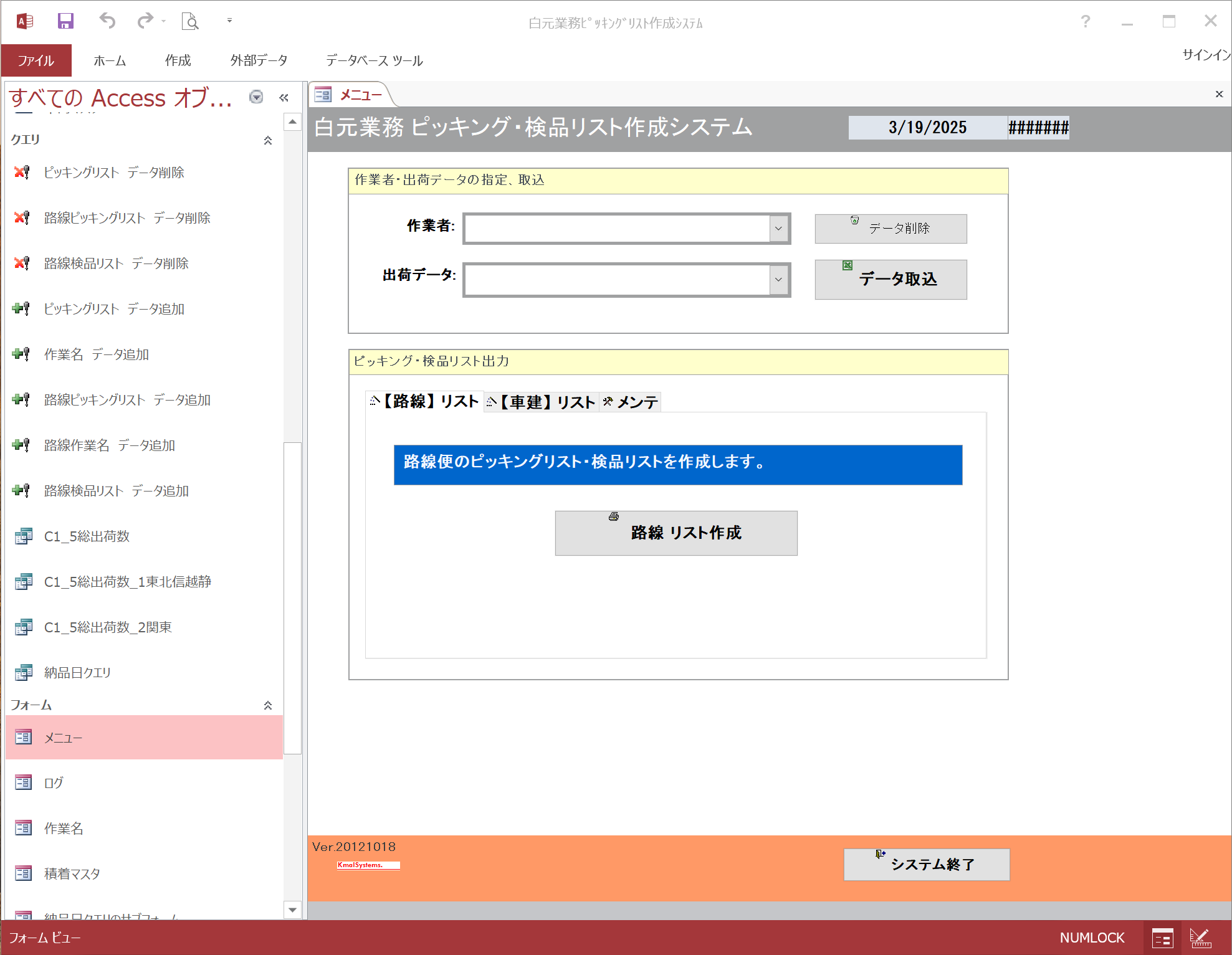

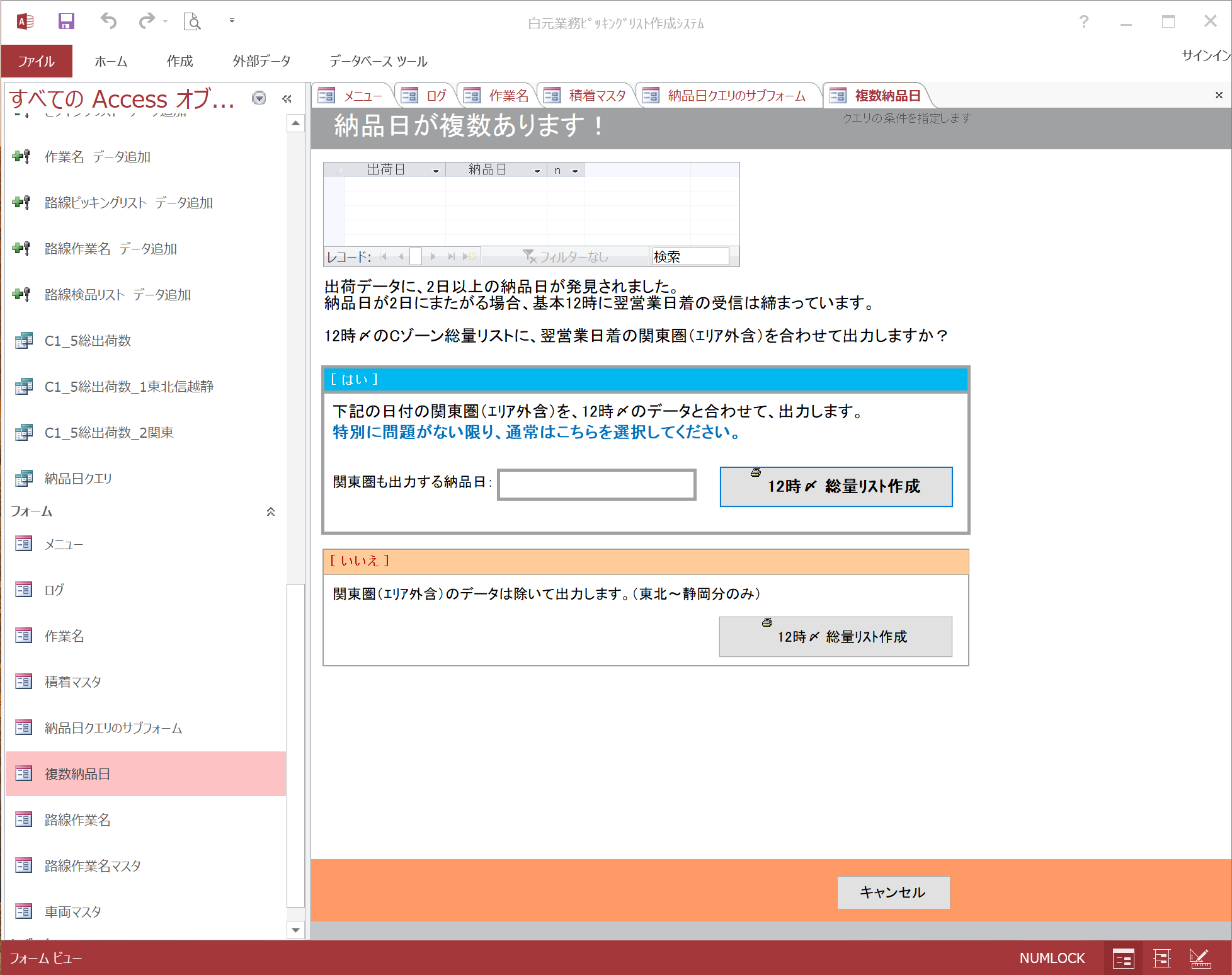

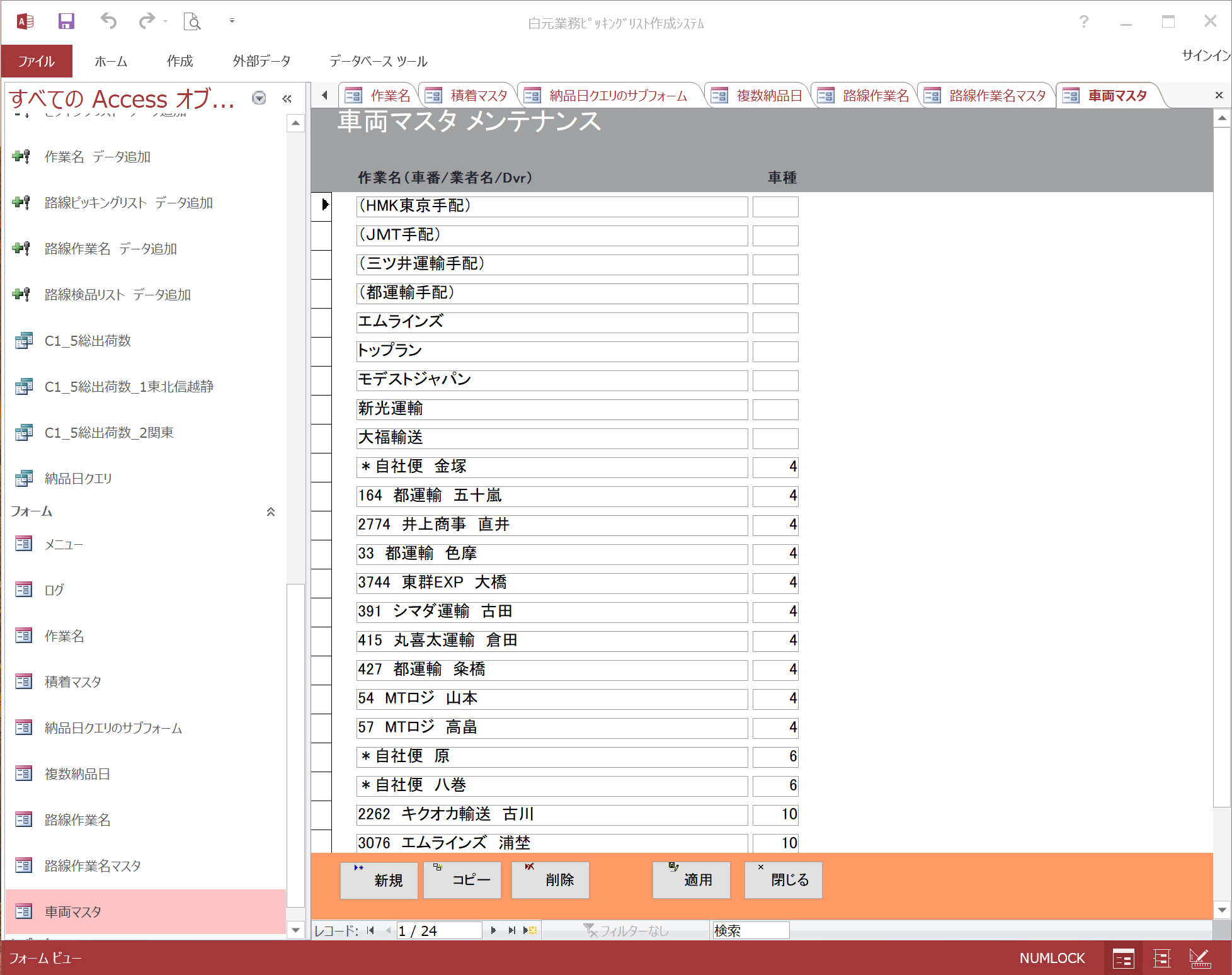

Developed a new picking-list system using Microsoft Access that ingests data directly from the core system. The UI was redesigned for an A4-sized format to enhance usability: larger typography, elimination of unnecessary details, and only essential information displayed. Through iterative optimization based on real-world picking operations—adjusting font sizes, item sequencing, spacing, and layout—we continuously refined the interface. Additional features included a productivity tracking section and visual inversion (highlighting) of frequently mis-picked items. As a result, client companies requested adoption of the system and the picking error rate dropped below 0.01%.

What I did

- UX / UI

- Typography

- Programming